Project POIR 01.01.01

As part of the project entitled: “Upscaling and development of technology for biopurification of air from VOCs and odors in a Compact Three-Phase Bioreactor Battery, in order to implement it in new industries” under the Smart Growth Operational Programme, Measure 1.1. “R&D projects of enterprises”, co-financed by the European Regional Development Fund

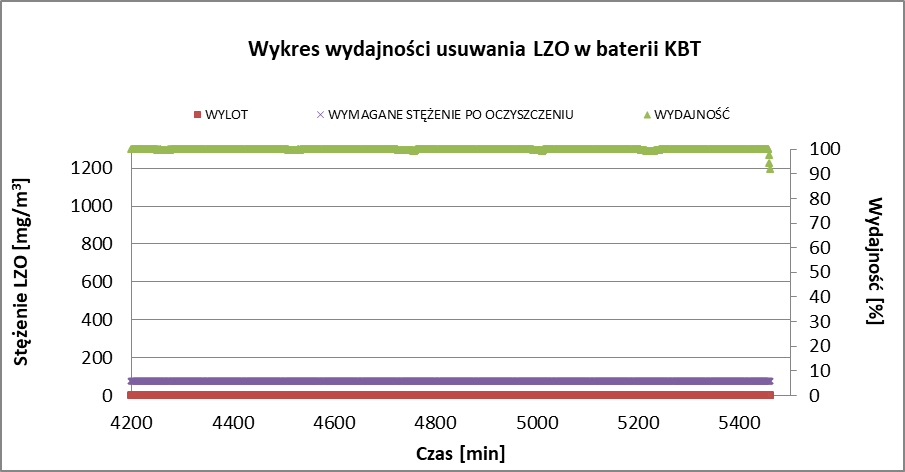

In connection with the implementation of the POIR 1.1.1. project entitled: “Upscaling and development of technology for air biopurification from VOCs and odors in a battery of compact three-phase bioreactors for implementation in new industries,” Ekoinwentyka sp. z o. o. conducted tests on the effectiveness of air biopurification in a battery of two compact three-phase bioreactors (KBT). Measurements were conducted continuously from September 10, 2020, to November 27, 2020, at Enduser’a, whose main activity is the production and painting of plastic parts, primarily for the automotive industry, in Europe.

The aim of the research is to evaluate the effectiveness of biopurification of air from paint lines operated by the Enduser production facility using a battery of KBT reactors in two different configurations: serial and parallel. Laboratory-scale KBT test reactors were used for the research.

Bioreactors in the fight for clean air!!!

The ” Bioreactors in the Fight for Clean Air!!! ” conference, held on July 27, 2021, at the University of Silesia in Katowice, attracted representatives of businesses and scientists from the region and around the world for the third time. The event provided an opportunity to listen to and exchange experiences with experts and practitioners respected in the environmental protection industry. Lakiernictwo Przemysłowe was pleased to provide media patronage for the conference.

The main objective of the conference was to present the results of research and development works carried out by Ekoinwentyka as part of the project “Upscaling and development of technology for biopurification of air from VOCs and odors in a Battery of Compact Three-Phase Bioreactors, in order to implement it in new industries” and to present the latest results of R&D works in the field of implementing innovations regarding biopurification of air from volatile organic compounds (VOCs) and odors.

A new feature of this year’s conference was the online presentation by Professor Eldon Rene – IHE Delft Institute for Water Education (The Netherlands).

During the event, it was possible to see a poster session prepared by students of the University of Silesia.

The first stage of the research was the technical adaptation of the air biopurification system to reduce VOCs and odors – the installation of a system consisting of two laboratory KBT reactors with full automation and measurement. This system was located next to the Enduser production facility. The equipment was commissioned on September 9, 2020, and on September 10, 2020, bacterial flora from the Ekoinwentyka culture was introduced, and from that point on, continuous measurements of the system’s efficiency were performed. The first days of the reactors’ operation were planned for the immobilization and growth of microorganisms, as well as the adaptation of the measuring devices. Therefore, the results of the initial phase of the research may differ from the assumed air biopurification efficiency.

The research carried out in the second stage, covering development research, was carried out using a battery of three new KBT reactors on a full industrial scale, purifying the air from the paint shop of the Enduser production plant.

The flow of the gas phase introduced into the KBT reactor battery was in the range of 24,000 – 45,000 m3/h.

The tests included: Assembly of the battery of three KBT reactors, construction of tanks in accordance with the design, checking the correctness of tank connections and chimney construction.

The average VOC concentration in purified gases was 0.9 mg/m 3 , the conversion rate during this period was K=99.8%. According to the plant’s environmental requirements, the VOC concentration after treatment should be up to 75 mg/m3 3 , which was fulfilled.